Hot Products

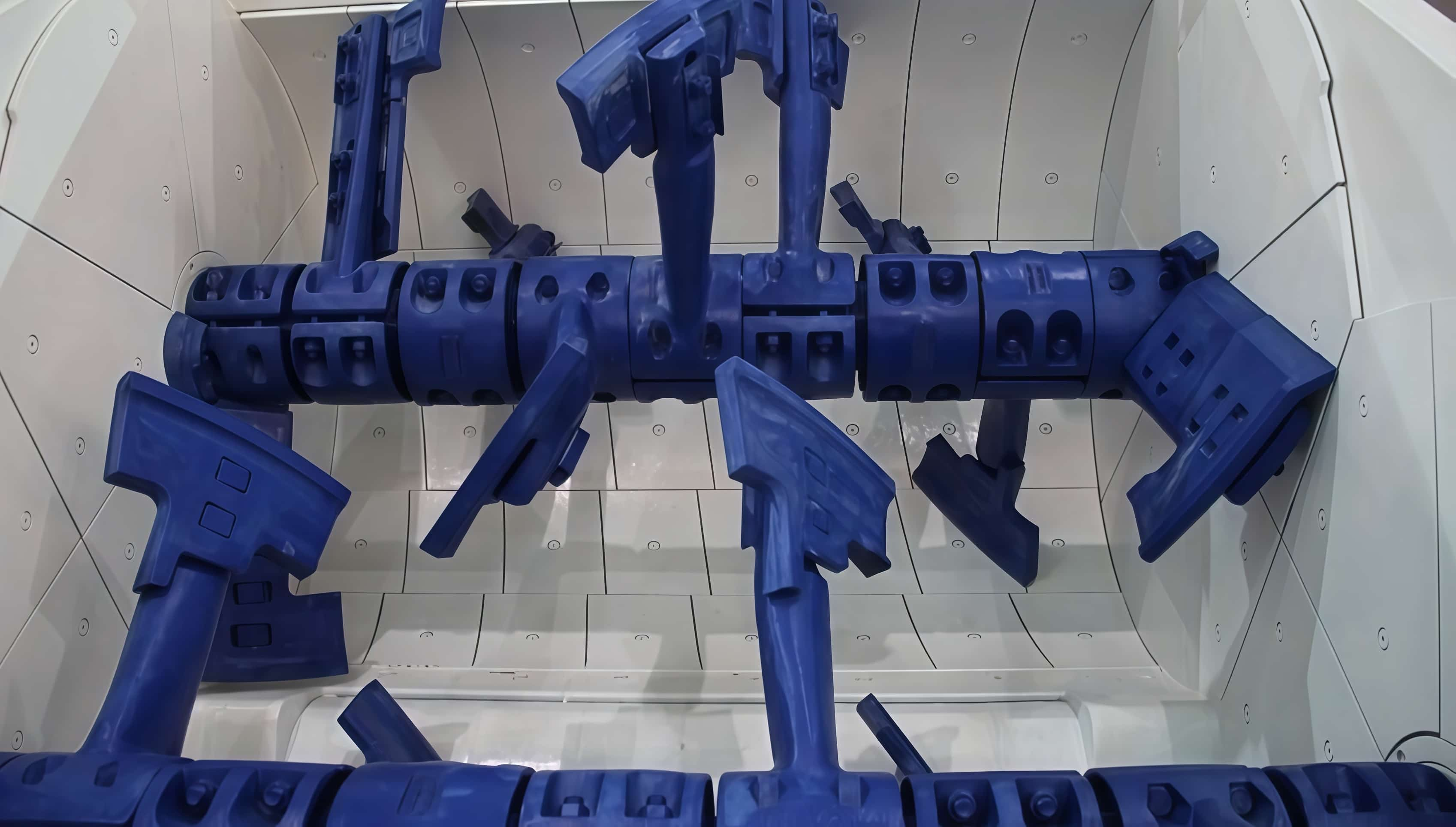

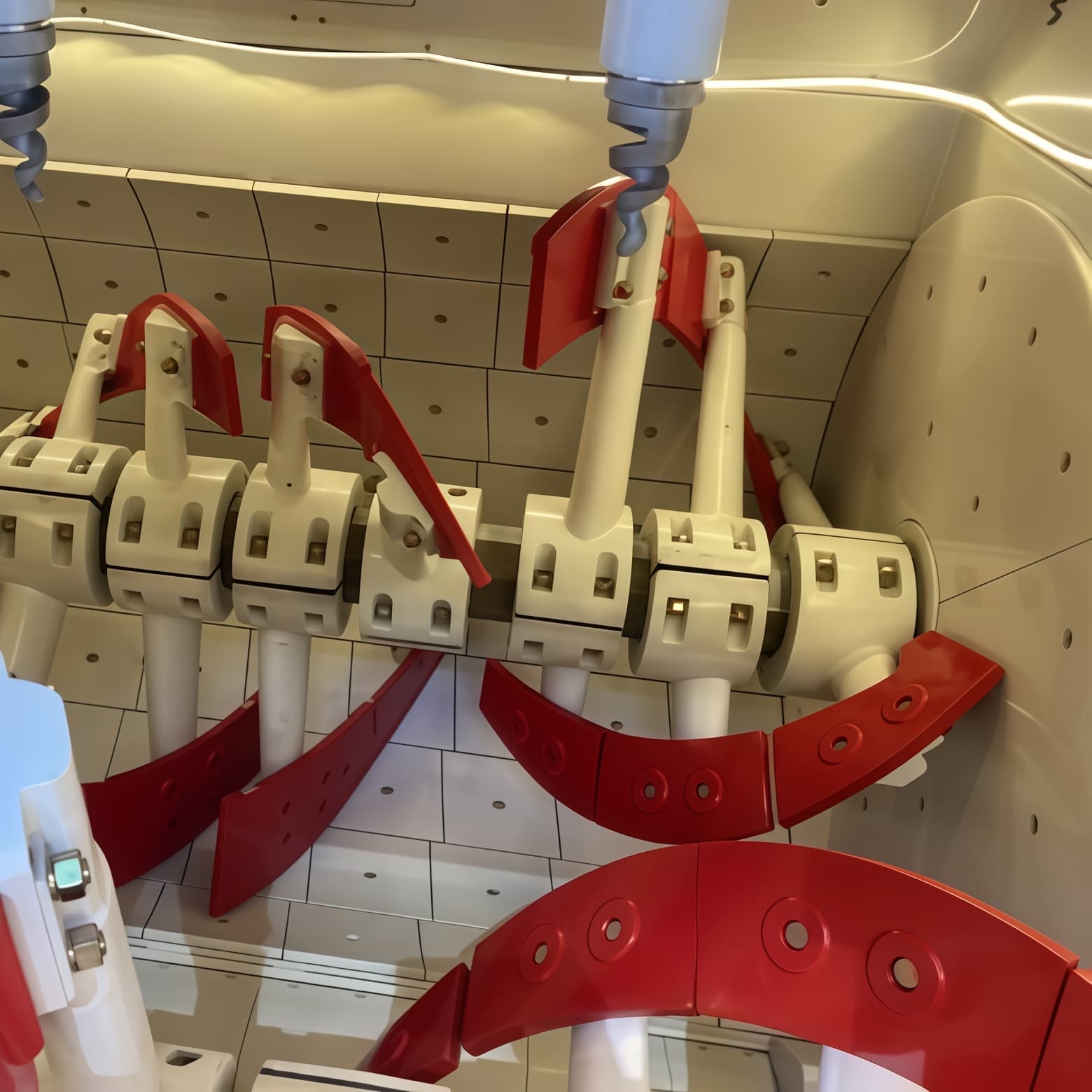

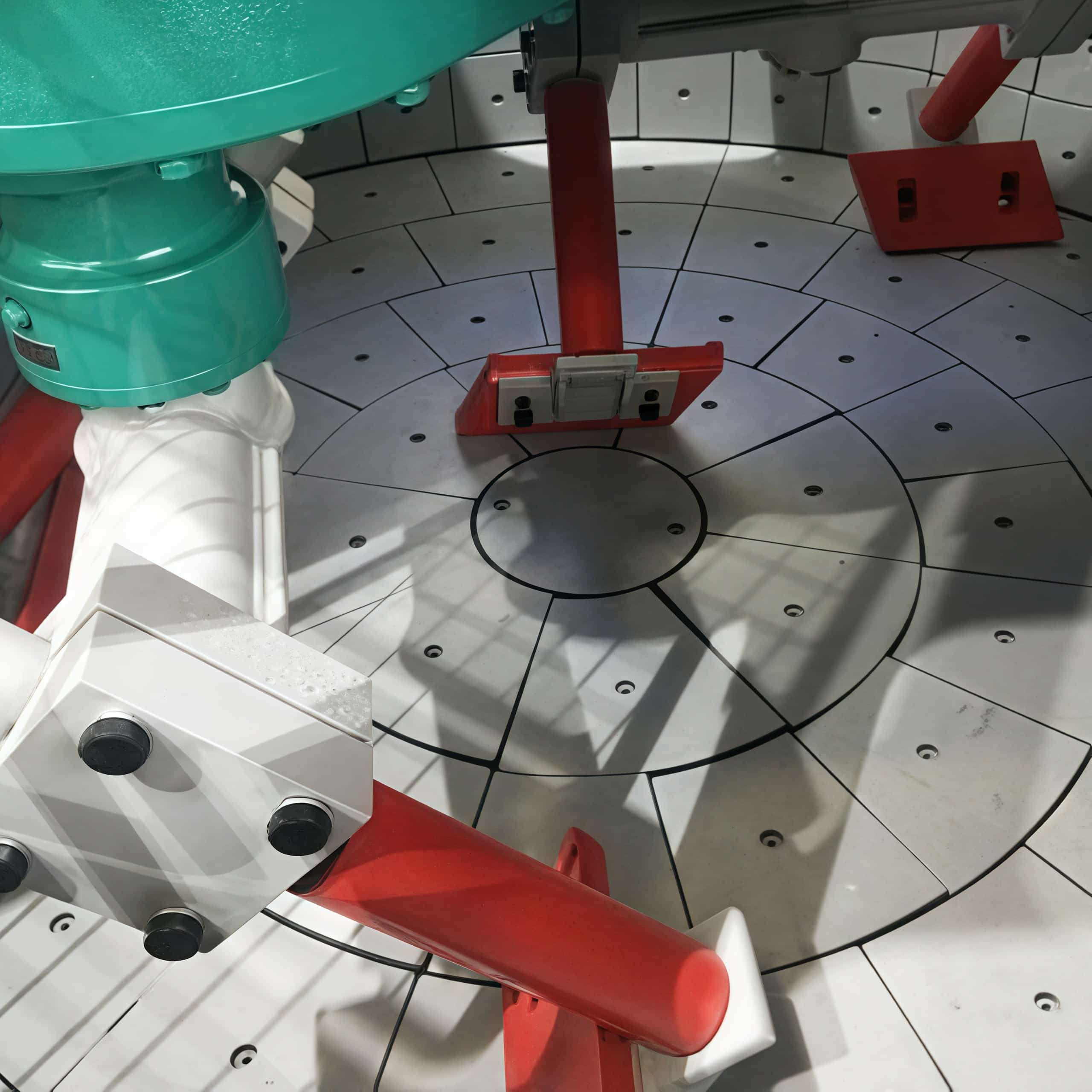

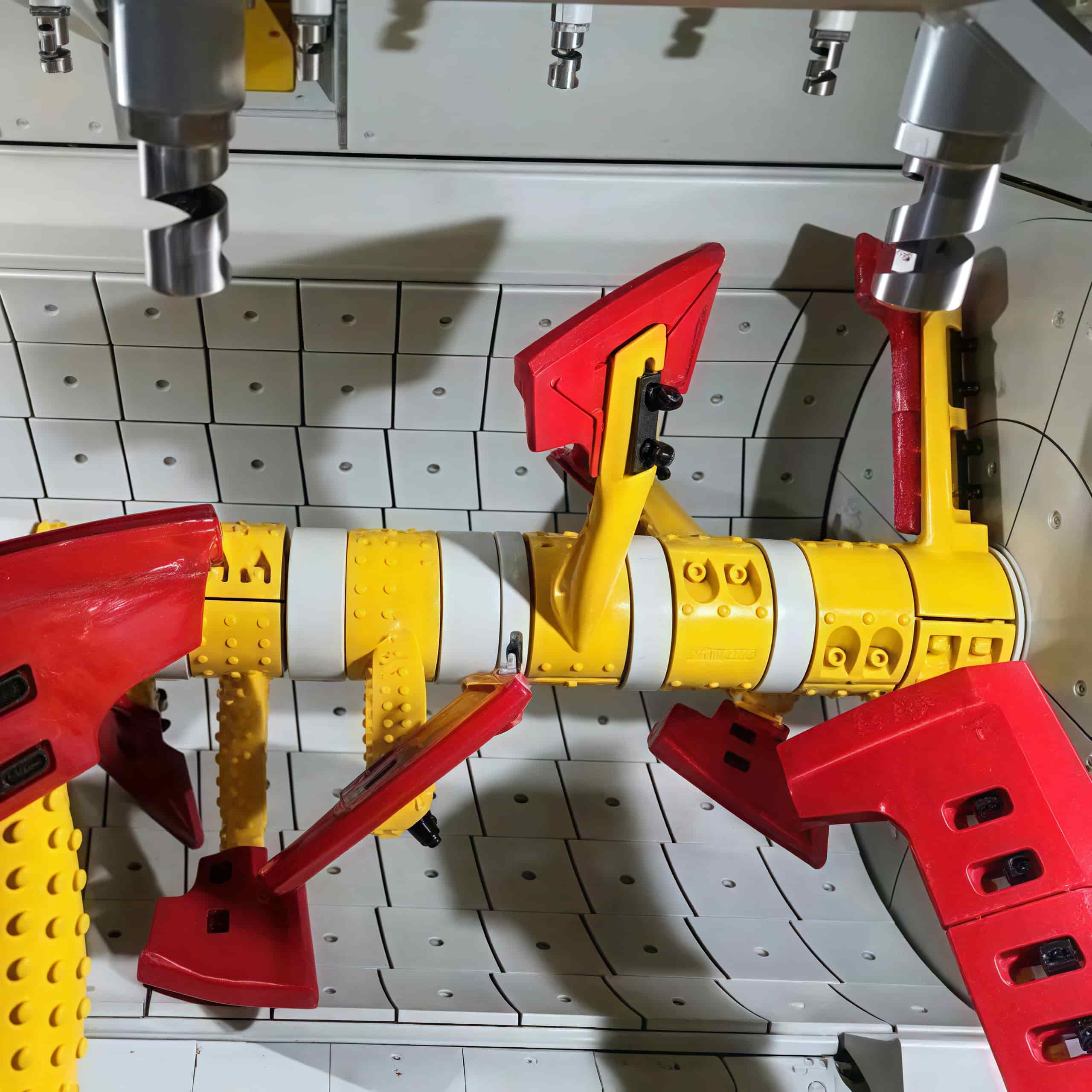

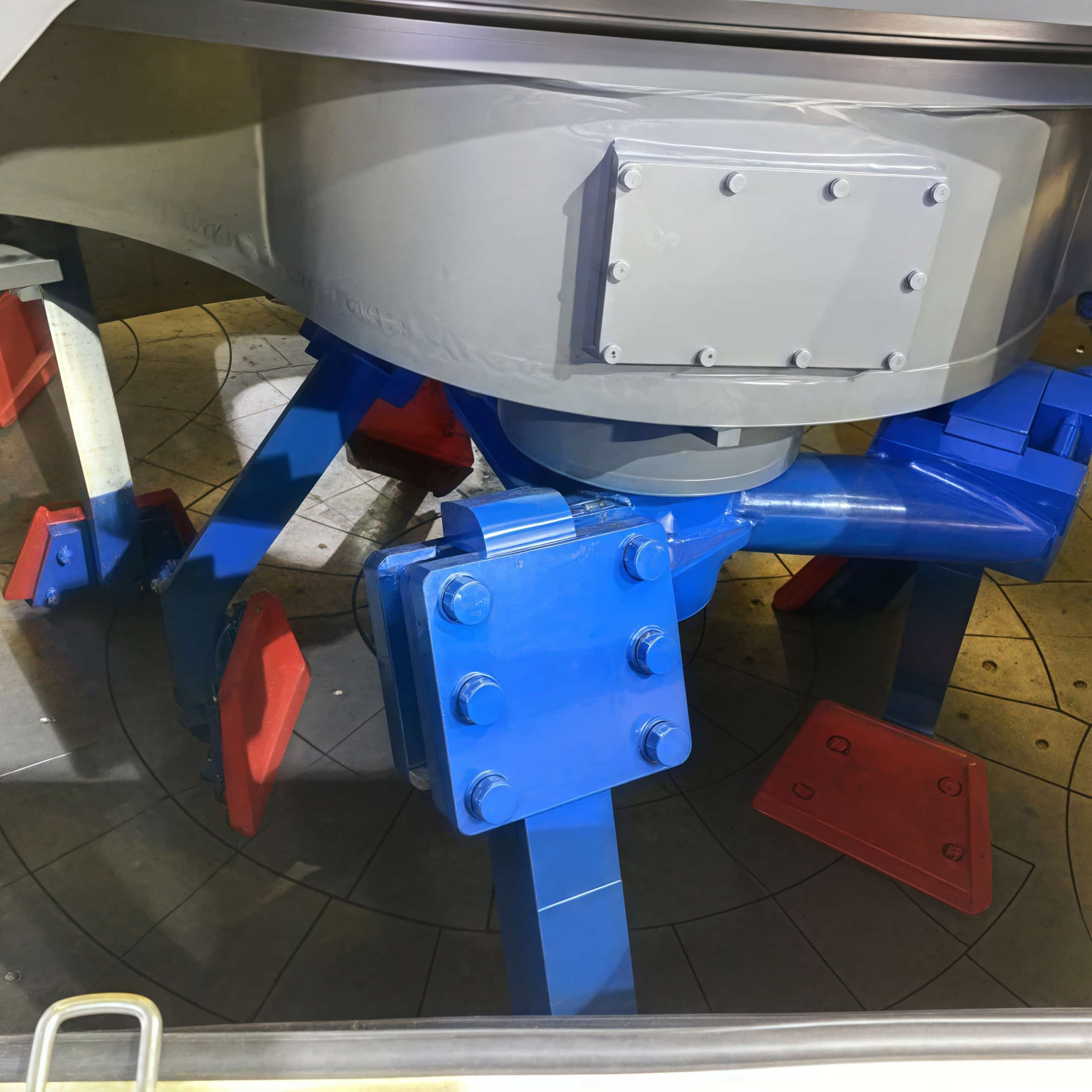

Maanshan Zhongrun company is specialized in the production of mixer accessories series,asphalt mixer,paver,and metallurgy,including concrete mixer,plant mixer mining, electric power,auto parts,chemical and other industries of wear-resistant alloy accessories.

Explore Products