What Are You Looking For?

What Are You Looking For?

At Zhongrun, we don’t just manufacture wear-resistant alloy parts—we engineer reliability. As a trusted supplier of concrete mixer spare parts and components for heavy-duty concrete equipment, our production process combines scientific rigor with cutting-edge technology to deliver unmatched durability. Here’s a closer look at how we transform raw materials into long-lasting solutions for the construction industry.

It all starts with chemistry. Our engineers meticulously select and balance alloying elements (like chromium, manganese, and carbon) to create materials specifically optimized for concrete mixer spare parts. This scientific approach ensures:

Superior resistance to abrasion from aggregates and cement

Enhanced toughness to withstand repetitive impact forces

Corrosion protection against moisture and harsh chemicals

By tailoring compositions to the demands of concrete equipment, we lay the groundwork for components that outlast industry standards.

Next, we melt the alloy in our medium-frequency induction furnaces. Unlike traditional methods, this technology ensures:

Rapid, uniform heating to eliminate impurities

Precise control over molten metal composition

Consistent quality across every batch

Strict temperature monitoring guarantees optimal fluidity and homogeneity, critical for casting complex shapes like mixer blades or liner plates without defects.

Our dual casting systems—Lost Foam and Vertical Flaskless Molding—combine flexibility with precision:

Lost Foam Casting: Ideal for intricate, near-net-shape parts (e.g., curved mixer blades), this method uses expandable polystyrene patterns to minimize machining waste and improve dimensional accuracy.

Vertical Flaskless Molding: Perfect for high-volume production of uniform components (e.g., liners, wear plates), this automated line ensures faster cycle times and exceptional surface finish.

Both methods reduce material waste while maintaining the structural integrity required for concrete equipment operating in extreme conditions.

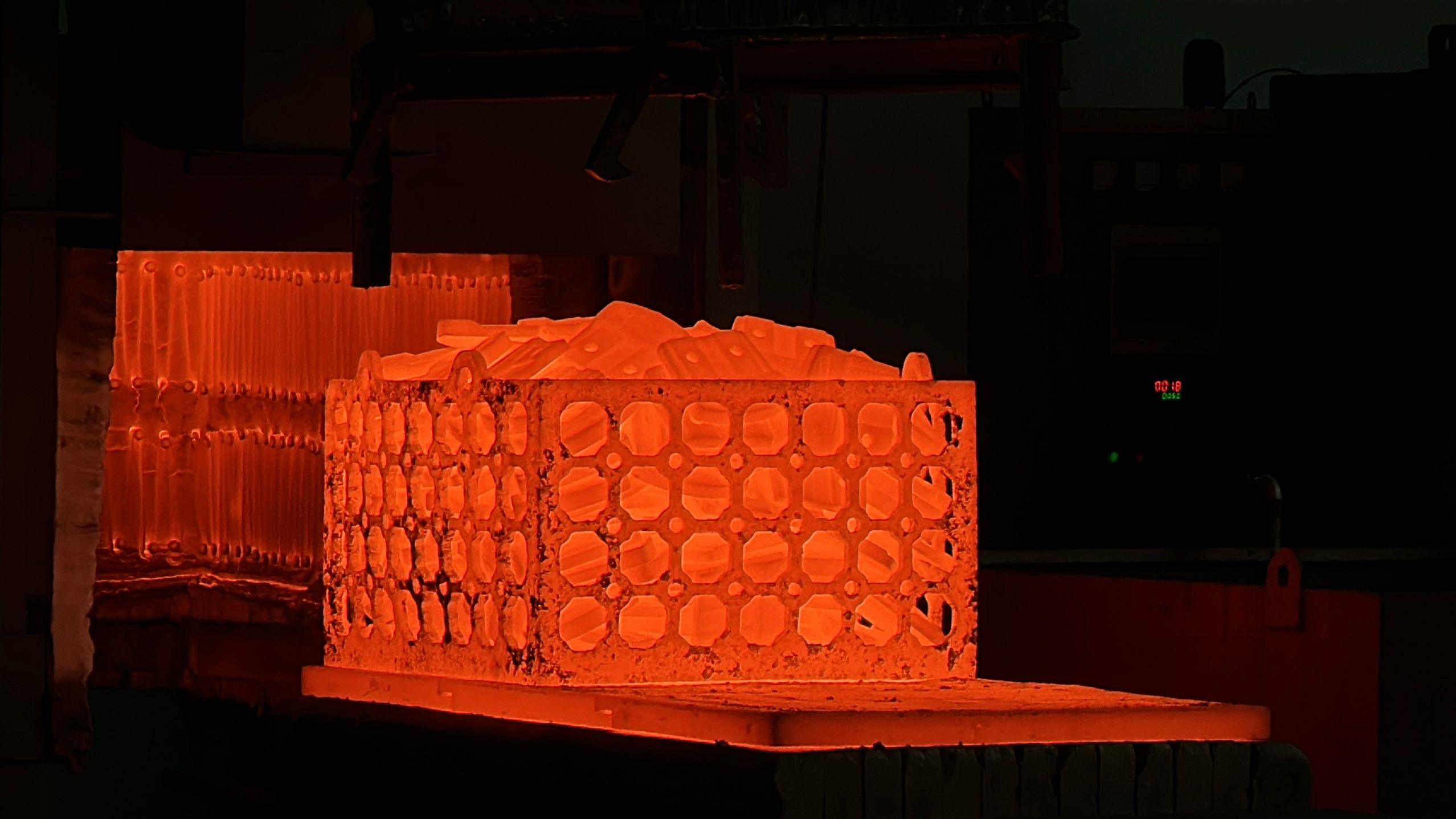

The final step is our advanced heat treatment process. Through controlled quenching and tempering, we:

Enhance surface hardness to resist wear

Optimize core toughness to prevent cracking

Stabilize the microstructure for long-term reliability

This stage is what transforms a cast part into a wear-resistant concrete mixer spare part capable of surviving millions of mixing cycles.

Every step in our workflow is designed to solve real-world challenges:

Longer Lifespan: Parts endure abrasive concrete mixes and harsh job sites, reducing replacement frequency.

Lower Downtime: Consistent quality means fewer unexpected failures.

Cost Savings: Durable components cut long-term maintenance costs for mixer trucks, batching plants, and more.

“In the world of concrete equipment, there’s no room for shortcuts,” says [CEO/Technical Director Name]. “From alloy design to heat treatment, our process ensures every part we produce meets the highest standards of durability and performance—because we know your machinery can’t afford to stop.”

About Zhongrun ![]()

Specializing in wear-resistant alloy components for concrete mixer spare parts and concrete equipment, [Your Company Name] leverages decades of metallurgical expertise and innovative manufacturing technologies. Trusted by contractors and OEMs globally, we’re committed to keeping concrete operations running smoother, longer, and stronger.