What Are You Looking For?

What Are You Looking For?

Introduction

In the world of engineering machinery, wear-resistant alloy castings—such as high-chromium cast iron and cast steel—are the unsung heroes that keep equipment like concrete mixers running smoothly under extreme conditions. However, their durability and performance hinge on one critical process: heat treatment. This blog dives into the science of quenching and tempering, explaining why these steps are indispensable for manufacturing high-quality wear-resistant components. We’ll also highlight how ZRZN Intelligent Equipment Co., Ltd., a leading manufacturer of alloy castings for concrete mixers and mining machinery, has mastered these techniques to deliver unparalleled product performance.

Wear-resistant alloys like high-chromium cast iron (HCCI) and cast steel are prized for their hardness and abrasion resistance. Yet, their raw forms are brittle and prone to cracking. Heat treatment—specifically quenching and tempering—transforms these materials into durable, reliable components by:

Enhancing Hardness: Rapid cooling (quenching) locks in a hardened microstructure.

Balancing Toughness: Tempering reduces brittleness while preserving strength.

Eliminating Stress: Proper heat treatment minimizes internal stresses that cause deformation.

Without these steps, components like mixer blades or crusher liners would fail prematurely under heavy loads.

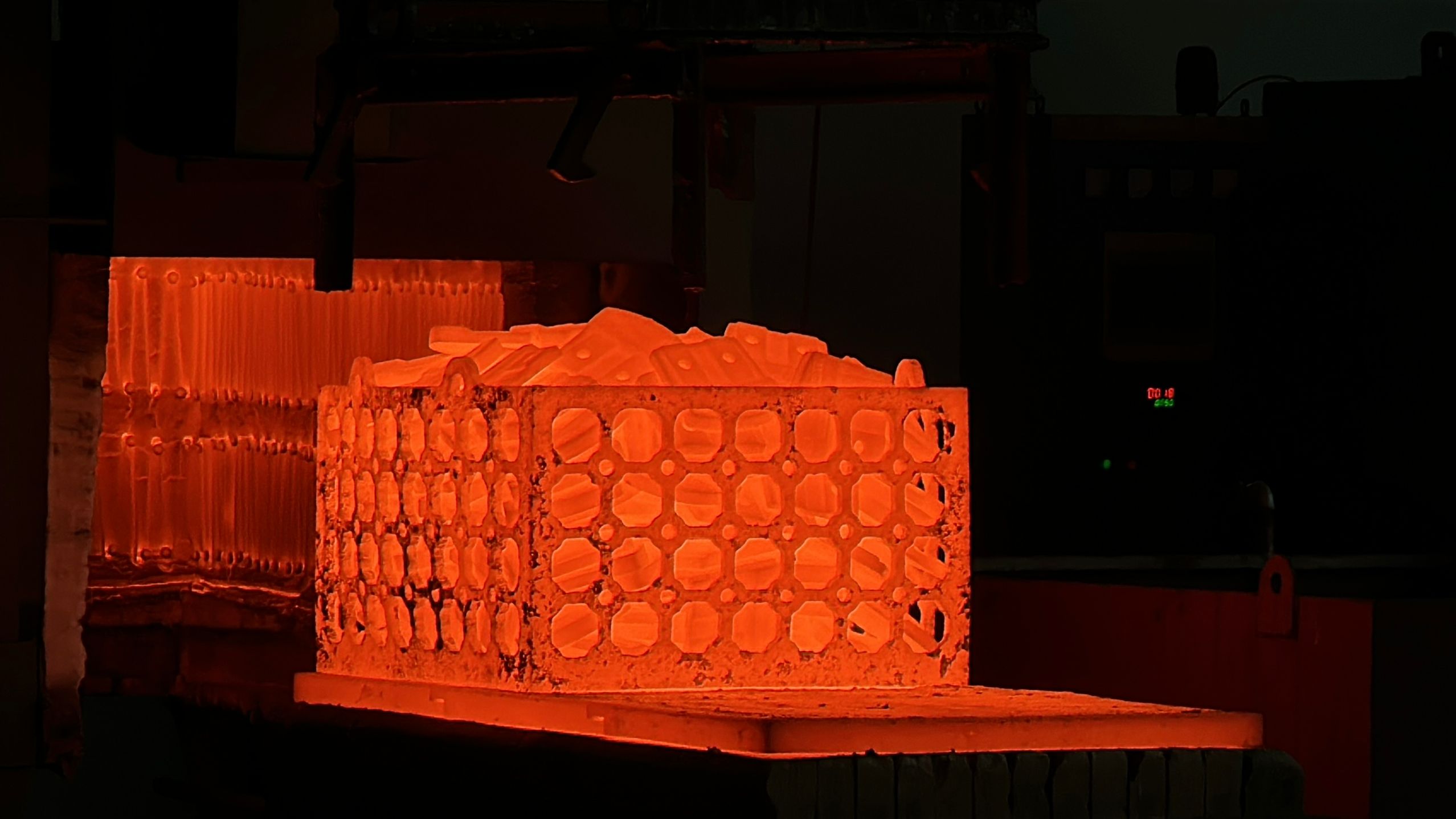

Quenching involves heating the alloy to a critical temperature (e.g., 900–1000°C for HCCI) and rapidly cooling it in oil, water, or air. This creates a martensitic structure, maximizing hardness. However, rapid cooling can introduce internal stresses, leading to warping or cracking.

ZRZN’s Expertise:

With decades of experience, ZRZN has refined a proprietary quenching process. Our advanced vertical flexible molding lines and precise temperature control ensure uniform cooling rates, eliminating uneven hardening and minimizing stress buildup. This results in components with exceptional quench hardiness (up to 54 HRC) and dimensional stability.

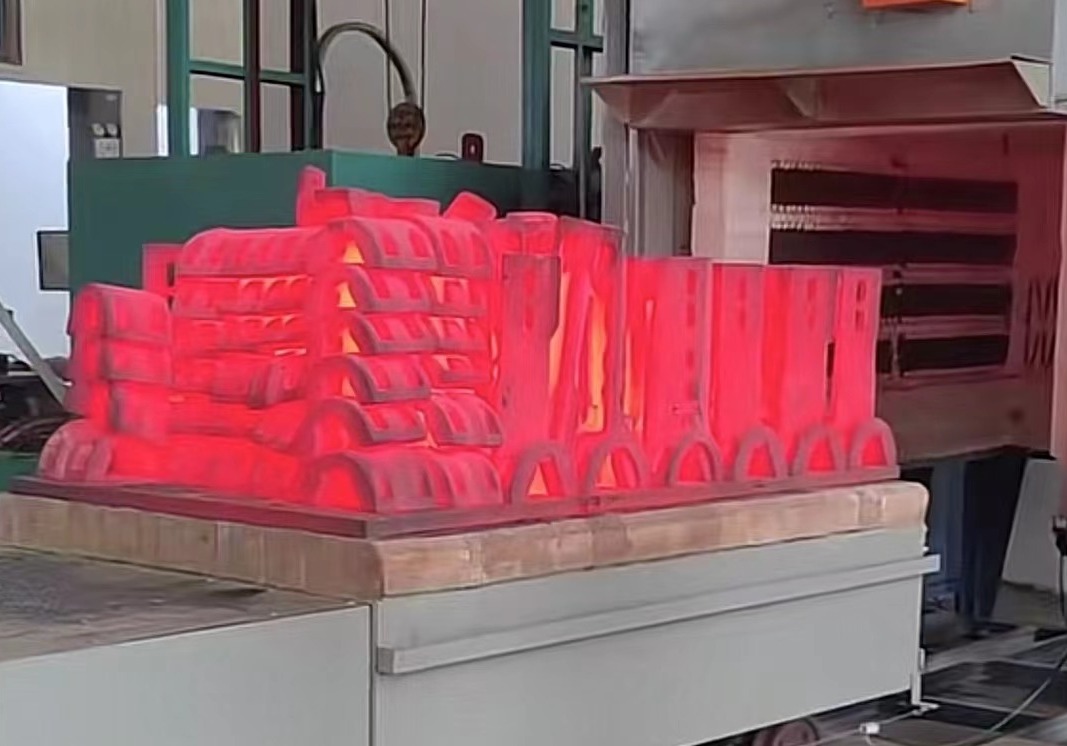

Tempering reheats quenched alloys to a lower temperature (200–500°C), allowing controlled relaxation of the microstructure. This step:

Reduces brittleness while retaining hardness.

Improves impact resistance (critical for concrete mixer parts).

Eliminates residual stresses from quenching.

ZRZN’s Innovation:

Our engineers have developed a multi-stage tempering technique tailored for high-chromium cast iron and cast steel. By optimizing time-temperature parameters, we achieve a perfect balance of hardness (50–58 HRC) and toughness (impact resistance up to 15 J/cm²). This ensures components withstand abrasive materials in concrete mixing or mining operations.

As a National High-Tech Enterprise and trusted supplier for global engineering machinery brands, ZRZN combines cutting-edge technology with deep metallurgical expertise:

✅ Proprietary Heat Treatment “Secret Recipe”:

Our patented processes, developed over 10+ years, ensure uniform quenching depth and zero deformation—even for complex geometries like shield machine cutters or mixer blades.

✅ State-of-the-Art Facilities:

Automated medium-frequency furnaces and AI-driven temperature monitoring systems guarantee consistency across batches.

✅ Sustainability Focus:

Eco-friendly quenching oils and energy-efficient practices align with global green manufacturing standards.

Concrete mixer blades and liners face relentless abrasion from aggregates. ZRZN’s heat-treated HCCI components offer:

Extended Lifespan: 2–3x longer than untreated alternatives.

Reduced Downtime: Superior wear resistance minimizes replacement frequency.

Cost Efficiency: Lower lifecycle costs for construction and mining companies.

Heat treatment is not just a step in manufacturing—it’s the backbone of durability for wear-resistant alloy castings. At ZRZN company, we’ve turned this science into an art, perfecting quenching and tempering to deliver components that outperform industry standards.

Looking for reliable, high-performance alloy castings for concrete mixers or mining equipment? Contact us today to explore how our heat treatment expertise can elevate your machinery’s performance.