What Are You Looking For?

What Are You Looking For?

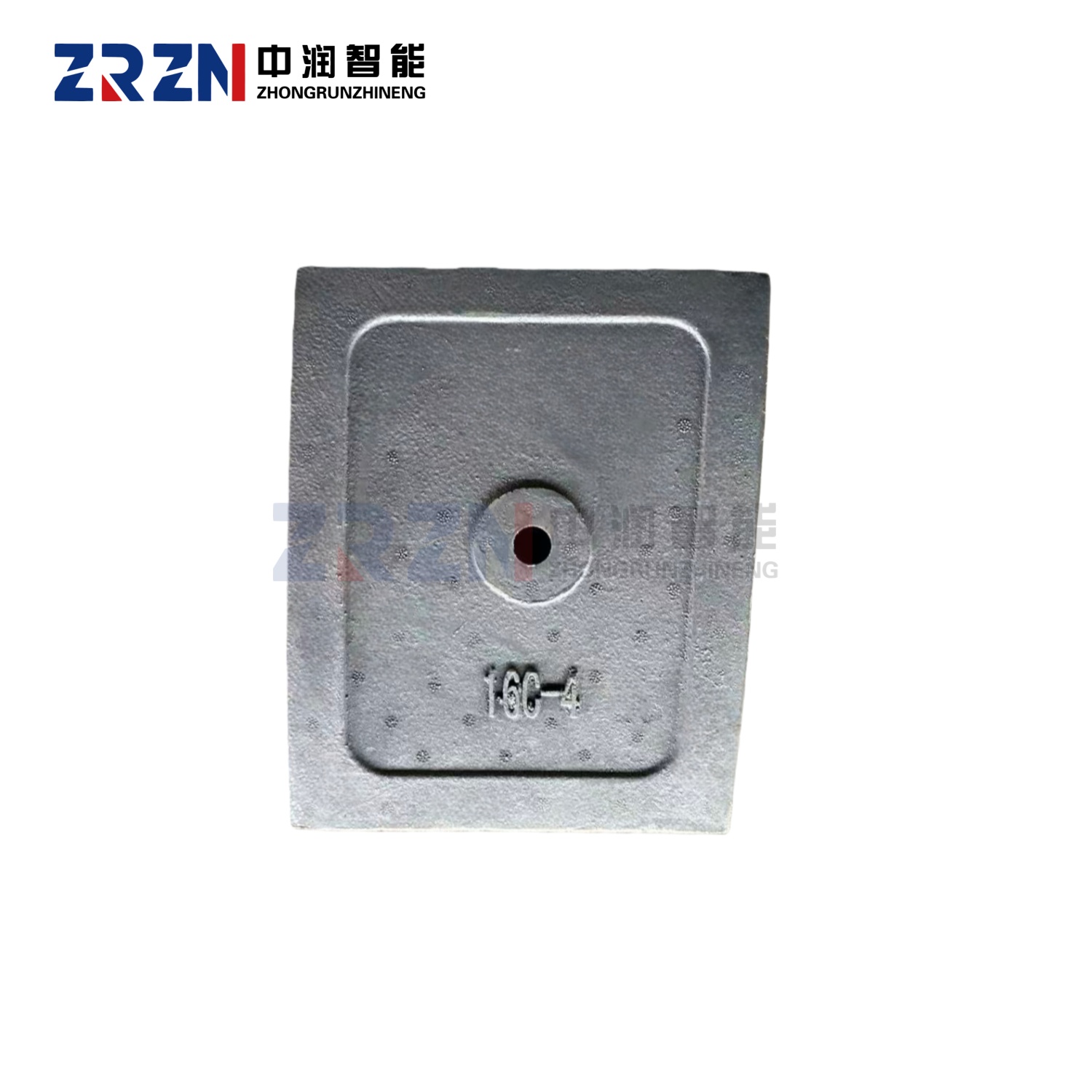

Ensure unmatched protection and sustained mixing efficiency for your TTM concrete mixer with our precision-engineered Trapezoidal Liner (Model 16C-4).

Order(MOQ):

1000kgGoods Stock:

1000Payment:

T/T, L/C, Paypal, Western UnionMarket Price:

$3Price:

$1.98/1000kgPrice Range:

1000 - 5000/$1.96Price Range:

5000 - 10000/$1.93Product Origin:

AnhuiColor:

CustomizedShipping Port:

ShanghaiLead Time:

15-30days| Description: |

Ensure unmatched protection and sustained mixing efficiency for your TTM concrete mixer with our precision-engineered Trapezoidal Liner (Model 16C-4). This specialized liner is not just a wear part; it is a geometrically optimized shield designed for the specific contours and operational dynamics of TTM mixing equipment. As a National High-Tech Enterprise and a contributor to the national standard for high-chromium wear-resistant castings (T/CISA), our engineering begins with a deep analysis of wear patterns. The unique trapezoidal design is manufactured using our advanced lost foam casting line, a process that excels in producing complex, near-net shapes with exceptional dimensional stability and surface integrity. This precise geometry ensures seamless interlocking installation, eliminates installation gaps that accelerate wear, and promotes a consistent, vortex-free material flow critical for producing homogeneous concrete batches.

The legendary durability of the 16C-4 liner is forged in our foundry through a fusion of precise engineering and material science. We begin with a high-purity melt in our medium-frequency induction furnaces, allowing for strict control over the Material Composition to achieve an optimal balance of chromium, carbon, and other alloying elements. This specific chemistry is the blueprint for performance. Through our proprietary multi-stage heat treatment, developed over decades of collaboration with research institutions, we engineer a superior Metallographic Structure. This refined microstructure is characterized by a uniform dispersion of hard carbides within a tough metallic matrix, resulting in a product that offers exceptional Surface Hardness (HRC 58-63) for abrasion resistance, combined with high Impact Toughness (>15 J/cm²) to withstand aggregate shock and significant Flexural Strength to resist deformation. This combination directly translates to a dramatically extended Service Life, reducing liner change-out frequency by up to 40% compared to standard alternatives.

Manufactured under our integrated ISO 9001 (Quality), ISO 14001 (Environmental), and ISO 45001 (Safety) management systems, each 16C-4 liner is a product of certified, traceable quality. Our in-house laboratory, equipped with optical emission spectrometers and metallographic microscopes, validates every batch. By choosing this liner, you invest in minimizing maintenance downtime, lowering your cost per cubic meter of concrete, and ensuring the long-term structural health of your TTM mixer drum.

| Features and Advantages |

1、Vertical Flaskless Molding Line: Enables high-speed, large-batch production with minimal dimensional variance.

| Product Parameters: |

| model number | tensile strength σb/Mpa |

tensile strength 0.2/Mpa |

elongation(%) | Fyi | ||

| new model number | equal old model number | minimum value | minimum value | minimum value | HBS Brinell hardness(BHS) |

main metallographic structure |

| QT400-18 | QT40-17 | 400 | 250 | 18 | 130-180 | ferritle |

| QT400-15 | - | 400 | 250 | 15 | 130-180 | ferritle |

| QT450-10 | QT42-10 | 450 | 310 | 10 | 160-210 | ferritle |

| QT500-7 | QT50-5 | 500 | 320 | 7 | 170-230 | ferritle+pearlite |

| QT600-3 | QT60-2 | 600 | 370 | 3 | 190-270 | pearlite+ferritle |

| QT700-2 | QT70-2 | 700 | 420 | 2 | 225-305 | pearlite |

| QT800-2 | QT80-2 | 800 | 480 | 2 | 245-335 | pearliteor tempered structure |

| QT900-2 | - | 900 | 600 | 2 | 280-360 | bainite or tempered martensite |

| Chemical composition(Mass fraction)(%) | |||||||||

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| KmTBN14Cr2-DT | 2.4~3.0 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.10 | ≤0.15 |

| KmTBN14Cr2-GT | 3.0~3.6 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr9Ni5 | 2.5~3.6 | ≤2.0 | ≤2.0 | 7.0-11.0 | ≤1.0 | 4.5~7.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr2 | 2.1~3.6 | ≤12 | ≤2.0 | 1.5~3.0 | ≤1.0 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.15 |

| KmTBCr8 | 2.1~3.2 | 1.5~2.2 | ≤2.0 | 7.0~11,0 | ≤1.5 | ≤1.0 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmlBCr12 | 2.0~3.3 | ≤1.5 | ≤2.0 | 11.0~14.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr15Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 14.0~18.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr20Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 18.0~23.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23.0~30.0 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.1 |

model number |

equal old model number |

Chemical composition(Mass fraction)(%) | Residual element |

||||

| C≤ | Si≤ | Mn≤ | S≤ | P≤ | |||

| ZG200-400 | 2G15 | 0.20 | 0.50 | 0.80 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG230-450 | ZG25 | 0.30 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG270-500 | ZG35 | 0.40 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG310-570 | 2G45 | 0.50 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG340-640 | ZG55 | 0.60 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| Packaging & Shipment |

| FAQ |

1.Q: Could you introduce your company’s business nature and production qualifications?

A: We are a professional manufacturer specializing in wear parts production with over two decades of industry expertise.

2.Q: How can we arrange a visit to your production facility?

A: We warmly welcome visits to our manufacturing base at any time. Our sales team will tailor a dedicated inspection itinerary for you.

3.Q: What core material systems do you utilize?

A: We employ engineered materials such as high-chromium cast iron, ductile cast iron, cast steel, and alloy steel. Material selection is scientifically optimized based on specific operational conditions and performance requirements.

4.Q: What payment methods do you support?

A: We accept international trade settlement methods including T/T and L/C. Flexible payment terms can be negotiated for long-term strategic partners.

5.Q: Do you offer customized branding services?

A: Yes, we provide end-to-end customization solutions covering industrial design, mold development, and product marking.

6.Q: How does your quality assurance system operate?

A: Our facility features professional-grade inspection equipment and a three-stage verification protocol: Incoming material inspection; Batch-specific process quality validation; Pre-shipment certification.

Tags :