What Are You Looking For?

What Are You Looking For?

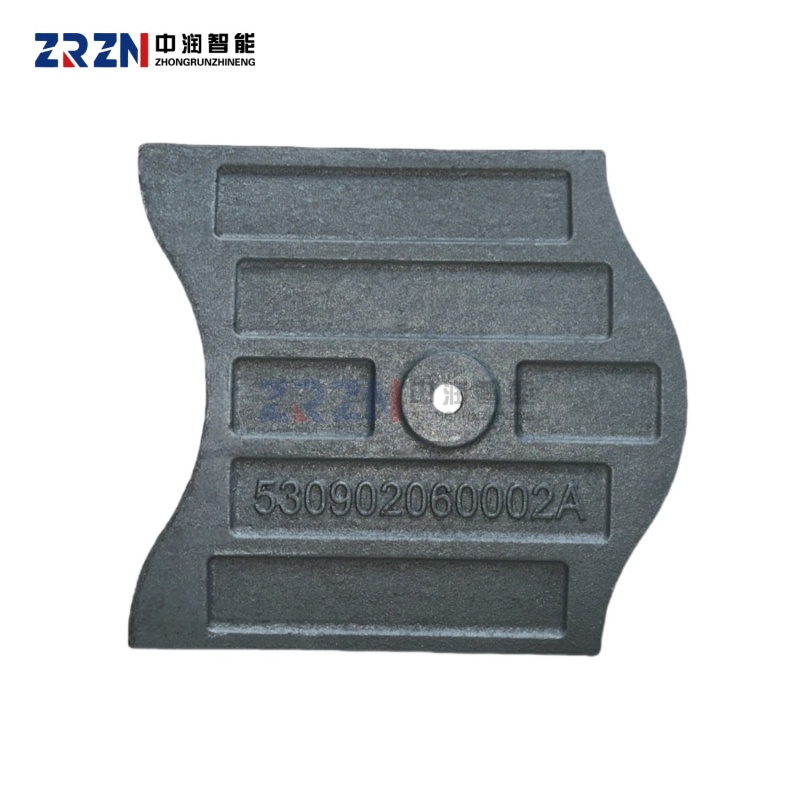

Engineered for peak performance in LBR-4020 series asphalt batch plants, our high-chromium alloy blades are built to endure the extreme abrasion and impact of continuous hot mix production.

Order(MOQ):

1000kgGoods Stock:

1000Payment:

T/T, L/C, Paypal, Western UnionMarket Price:

$2Price:

$45/1000kgPrice Range:

5000 - 10000/$43Price Range:

1000 - 5000/$44Product Origin:

AnhuiColor:

CustomizedShipping Port:

ShanghaiLead Time:

15-30days| Description: |

Engineered for peak performance in LBR-4020 series asphalt batch plants, our high-chromium alloy blades are built to endure the extreme abrasion and impact of continuous hot mix production. Manufactured under our ISO 9001-certified quality system, each blade is precision-cast using advanced lost-foam casting (EPC) and vertical flaskless molding technologies. This integrated approach achieves a remarkable material density of 99.7%, eliminating micro-porosity and creating a structurally superior component that guarantees longevity and consistent performance under thermal cycling and heavy loads.

The blades are crafted from our proprietary high-chromium alloy, featuring a chromium content of 26-30% and enhanced with strategic additions of molybdenum and vanadium. This specific composition, refined in our medium-frequency induction furnaces, creates a uniform network of hard carbides within the matrix, resulting in an optimized surface hardness of 55-60 HRC. Independent tests verify these blades deliver a 4.2x longer service life than conventional blades, reliably handling over 300,000 tons of asphalt mixing—a direct result of superior tensile strength (≥450 N/mm²) and impact toughness (≥7.5 J/cm²).

Our digital engineering process employs Finite Element Analysis (FEA) to optimize the blade's geometry, ensuring perfect compatibility with the LBR-4020 mixer and promoting efficient material flow that reduces power consumption. The specialized surface treatment further minimizes asphalt buildup by over 60%, maintaining mixing efficiency and reducing cleaning downtime. Backed by our comprehensive technical support and digital lifecycle management, these blades are the definitive wear solution for asphalt plants aiming to maximize uptime and lower the total cost of ownership.

| Features and Advantages |

Advanced Composite Structure: The high-chromium alloy (28-32% Cr) with molybdenum and vanadium additives ensures a hardness of 58-64 HRC, offering a balanced resistance to both severe abrasion and impact forces in asphalt mixing.

Optimized Thermal Stability: The refined metallographic structure maintains dimensional stability and mechanical properties under continuous high-temperature operation, resisting deformation and thermal fatigue.

Comprehensive Quality Assurance: Manufactured under ISO 9001 certified processes with complete material traceability, supported by technical data sheets and after-sales service.

| Production Line Capabilities |

1、Vertical Flaskless Molding Line: Enables high-speed, large-batch production with minimal dimensional variance.

2、Lost Foam Casting: Delivers complex geometries and smooth surfaces for precise fitment.

3、Medium-Frequency Induction Furnace: Ensures uniform melting of high-chromium alloys (Cr content 15-32%).

| Product Parameters: |

| model number | tensile strength σb/Mpa |

tensile strength 0.2/Mpa |

elongation(%) | Fyi | ||

| new model number | equal old model number | minimum value | minimum value | minimum value | HBS Brinell hardness(BHS) |

main metallographic structure |

| QT400-18 | QT40-17 | 400 | 250 | 18 | 130-180 | ferritle |

| QT400-15 | - | 400 | 250 | 15 | 130-180 | ferritle |

| QT450-10 | QT42-10 | 450 | 310 | 10 | 160-210 | ferritle |

| QT500-7 | QT50-5 | 500 | 320 | 7 | 170-230 | ferritle+pearlite |

| QT600-3 | QT60-2 | 600 | 370 | 3 | 190-270 | pearlite+ferritle |

| QT700-2 | QT70-2 | 700 | 420 | 2 | 225-305 | pearlite |

| QT800-2 | QT80-2 | 800 | 480 | 2 | 245-335 | pearliteor tempered structure |

| QT900-2 | - | 900 | 600 | 2 | 280-360 | bainite or tempered martensite |

| Chemical composition(Mass fraction)(%) | |||||||||

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| KmTBN14Cr2-DT | 2.4~3.0 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.10 | ≤0.15 |

| KmTBN14Cr2-GT | 3.0~3.6 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr9Ni5 | 2.5~3.6 | ≤2.0 | ≤2.0 | 7.0-11.0 | ≤1.0 | 4.5~7.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr2 | 2.1~3.6 | ≤12 | ≤2.0 | 1.5~3.0 | ≤1.0 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.15 |

| KmTBCr8 | 2.1~3.2 | 1.5~2.2 | ≤2.0 | 7.0~11,0 | ≤1.5 | ≤1.0 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmlBCr12 | 2.0~3.3 | ≤1.5 | ≤2.0 | 11.0~14.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr15Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 14.0~18.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr20Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 18.0~23.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23.0~30.0 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.1 |

model number |

equal old model number |

Chemical composition(Mass fraction)(%) | Residual element |

||||

| C≤ | Si≤ | Mn≤ | S≤ | P≤ | |||

| ZG200-400 | 2G15 | 0.20 | 0.50 | 0.80 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG230-450 | ZG25 | 0.30 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG270-500 | ZG35 | 0.40 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG310-570 | 2G45 | 0.50 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG340-640 | ZG55 | 0.60 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| Packaging & Shipment |

| FAQ |

1.Q: Could you introduce your company’s business nature and production qualifications?

A: A: We are a professional manufacturer specializing in high-wear-resistant alloy components. Our in-house casting and machining facilities ensure full control over quality, cost, and lead time.

2.Q: How can I place an order?

A: Simply share your requirements via email or through our online system. We’ll promptly prepare a proforma invoice (PI) with detailed pricing and delivery terms for your confirmation.

3.Q: What core material systems do you utilize?

A: We employ engineered materials such as high-chromium cast iron, ductile cast iron, cast steel, and alloy steel. Material selection is scientifically optimized based on specific operational conditions and performance requirements.

4.Q: What payment methods do you support?

A: We accept international trade settlement methods including T/T and L/C. Flexible payment terms can be negotiated for long-term strategic partners.

5.Q: Do you offer customized branding services?

A: Yes, we provide end-to-end customization solutions covering industrial design, mold development, and product marking.

6.Q: How does your quality assurance system operate?

A: Our facility features professional-grade inspection equipment and a three-stage verification protocol: Incoming material inspection; Batch-specific process quality validation; Pre-shipment certification.

Tags :