What Are You Looking For?

What Are You Looking For?

Global construction demands drive wear-resistant alloy parts technology revolution in 2025. Our R&D team just cracked the code on chromium-molybdenum composite blends, achieving 40% longer service life in high-abrasion concrete mixing environments.

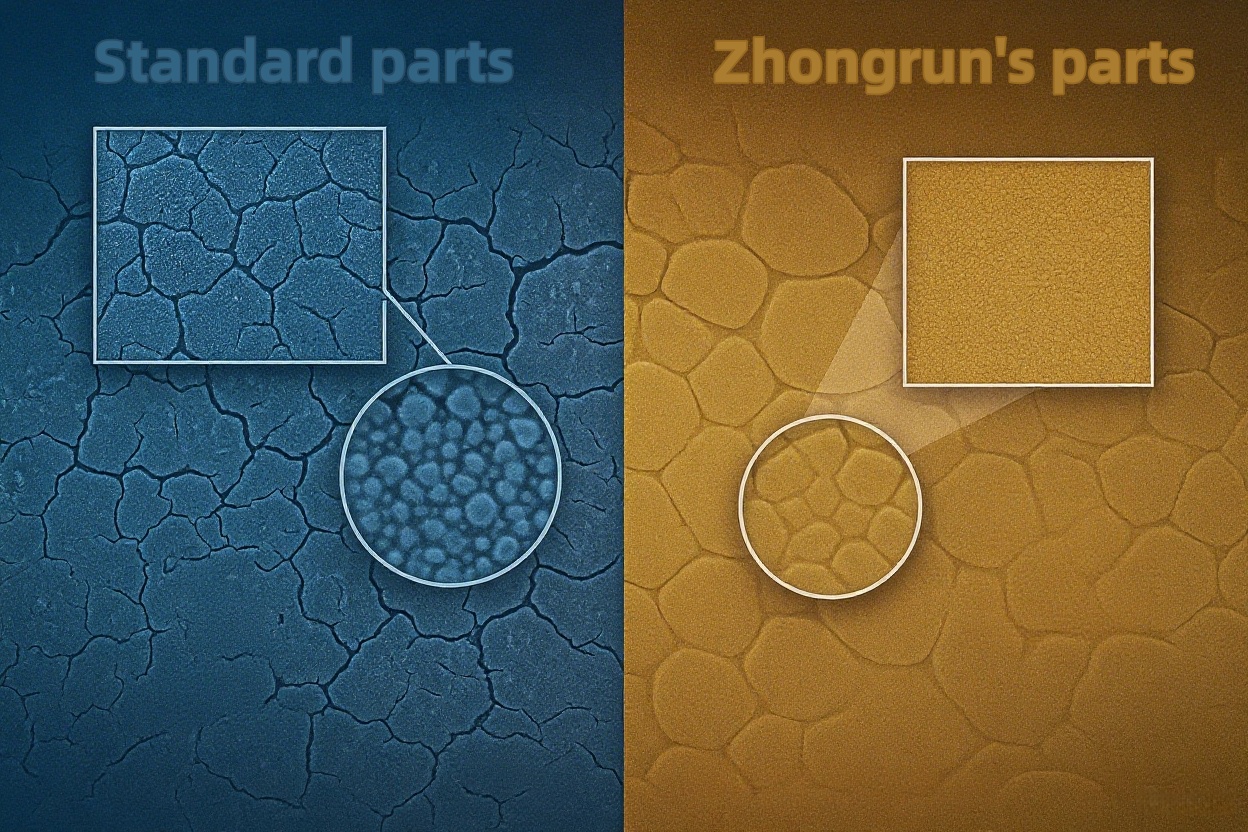

Field tests prove our patented mixer blades withstand extreme C40+ concrete corrosion 3x longer than industry standards. The nano-crystalline structure eliminates micro-cracking – the primary failure point in conventional alloys.

For batching plant operators, this translates to:

✓ 22% reduced downtime

✓ 17% lower cost per cubic meter

✓ ECO-Mode™ drum liners cutting energy use

Request your wear parts sample kit with 2025 formulations before July 30. Includes abrasion test reports for 8 concrete grades.