What Are You Looking For?

What Are You Looking For?

This L-type blade is engineered for high-output concrete mixing stations. Made from wear-resistant alloy steel, it ensures uniform mixing, reduces material buildup, and supports fast replacement to minimize downtime.

Brand:

SICOMAItem NO.:

BladeOrder(MOQ):

1000kgGoods Stock:

1000Payment:

T/T, L/C, Paypal, , Western UnionMarket Price:

$2.1Price:

$1.98/1000kgPrice Range:

5000 - 10000/$1.93Price Range:

1000 - 5000/$1.96Product Origin:

AnhuiColor:

CustomizedShipping Port:

ShanghaiLead Time:

15-30days| Description: |

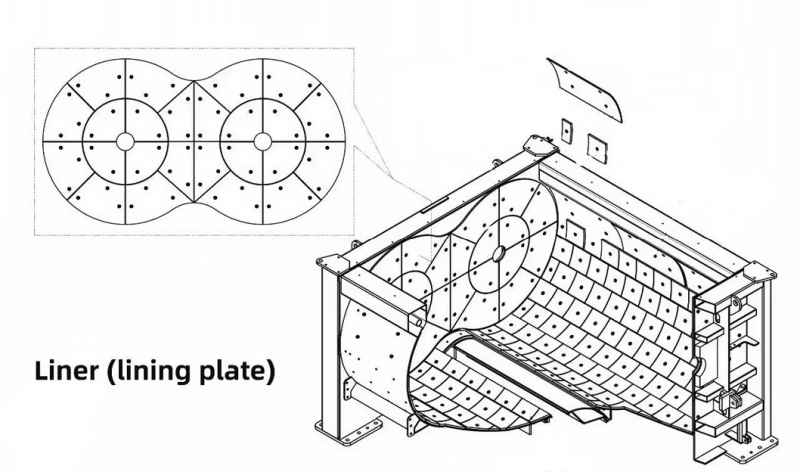

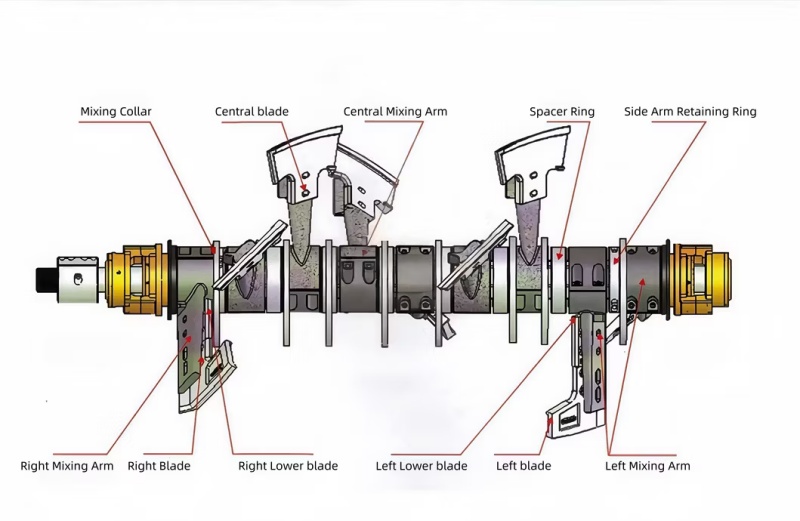

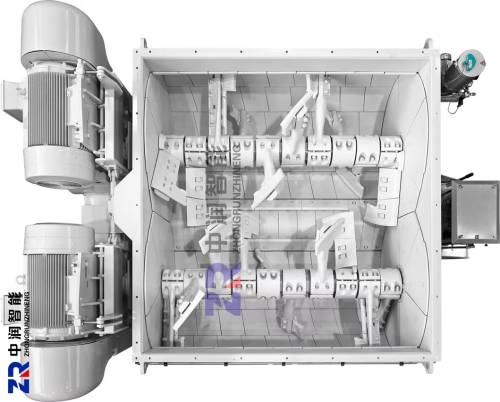

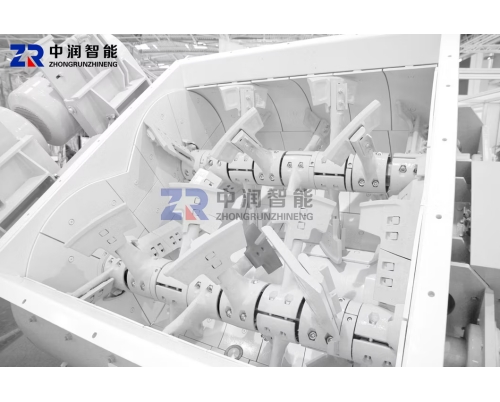

This L-shaped mixing blade is specifically designed for use in concrete batching plants and construction machinery. Manufactured from high-chromium cast iron or high-manganese steel, it delivers outstanding wear resistance and durability under abrasive working conditions. Suitable for SICOMA, SANY, ZOOMLION, and other common mixers, this blade provides reliable performance for high-volume concrete production.

| Key Features: |

Wear-Resistant Material

Made from premium-grade high chromium cast iron, this blade offers excellent resistance to abrasion from concrete, sand, and gravel. It lasts significantly longer than conventional carbon steel blades.

Efficient Mixing Performance

The L-shape and precision-cut edge design reduce dead zones and improve material turnover, ensuring faster and more uniform mixing results.

Corrosion-Resistant Surface

Coated with anti-corrosive treatment to prevent rusting and degradation when exposed to water, cement slurry, and chemical admixtures.

Modular Bolt-On Design

Easy to install and replace. The bolt-on modular design allows for quick changeouts in just minutes, minimizing maintenance downtime and keeping operations running smoothly.

Custom Fit & Compatibility

Compatible with various mixer models from leading brands. Custom sizes and hole positions can be produced based on customer drawings or specifications.

| Application Scenarios: |

Ready-mix concrete plants

Precast concrete factories

On-site concrete batching stations

Large-scale infrastructure projects requiring consistent mixing performance

|

|

|

|

| Why Choose Our Mixing Blades? |

Long service life: Reduces frequency of replacement

Low maintenance: Easy installation and minimal downtime

Enhanced productivity: Better mixing efficiency improves concrete quality

Trusted by industry leaders: Compatible with top brands like SICOMA, SANY, ZOOMLION

| Shipment: |

| Certifications: |

| Our Advantages: |

After Sales Service:

Initiate service requests by submitting detailed photos/videos of any concerns. Upon receiving your inquiry, our support team conducts a comprehensive technical evaluation within 24 hours, followed by a tailored resolution plan. Complementing this, we implement proactive follow-up consultations to monitor product performance and preemptively address potential wear patterns.

Quality Assurance:

Our rigorous quality assurance system ensures excellence at every stage. From stringent raw material testing prior to production, to real-time process monitoring and precision-driven inspections during manufacturing, and culminating in comprehensive final product evaluations—we uphold the highest standards to guarantee consistent performance and reliability.

Professional Expertise:

Leveraging over two decades of specialized industry experience, we deliver end-to-end solutions from prototype development to mass production. Our team provides seamless technical support, ensuring innovative design optimization, efficient manufacturing, and on-time delivery tailored to your unique requirements.

OEM/ODM Services:

We offer customized OEM/ODM solutions for high-wear components, including precision-engineered mixer blades, durable liners, and reinforced agitator arms. Partner with us for flexible design collaboration, material innovation, and scalable production that aligns with your operational needs and performance goals.

Our production line:

FAQ:

1.Q: Could you introduce your company’s business nature and production qualifications?

A: We are a professional manufacturer specializing in wear parts production with over two decades of industry expertise.

2.Q: How can we arrange a visit to your production facility?

A: We warmly welcome visits to our manufacturing base at any time. Our sales team will tailor a dedicated inspection itinerary for you.

3.Q: What core material systems do you utilize?

A: We employ engineered materials such as high-chromium cast iron, ductile cast iron, cast steel, and alloy steel. Material selection is scientifically optimized based on specific operational conditions and performance requirements.

4.Q: What payment methods do you support?

A: We accept international trade settlement methods including T/T and L/C. Flexible payment terms can be negotiated for long-term strategic partners.

5.Q: Do you offer customized branding services?

A: Yes, we provide end-to-end customization solutions covering industrial design, mold development, and product marking.

6.Q: How does your quality assurance system operate?

A: Our facility features professional-grade inspection equipment and a three-stage verification protocol: Incoming material inspection; Batch-specific process quality validation; Pre-shipment certification.

Tags :