What Are You Looking For?

What Are You Looking For?

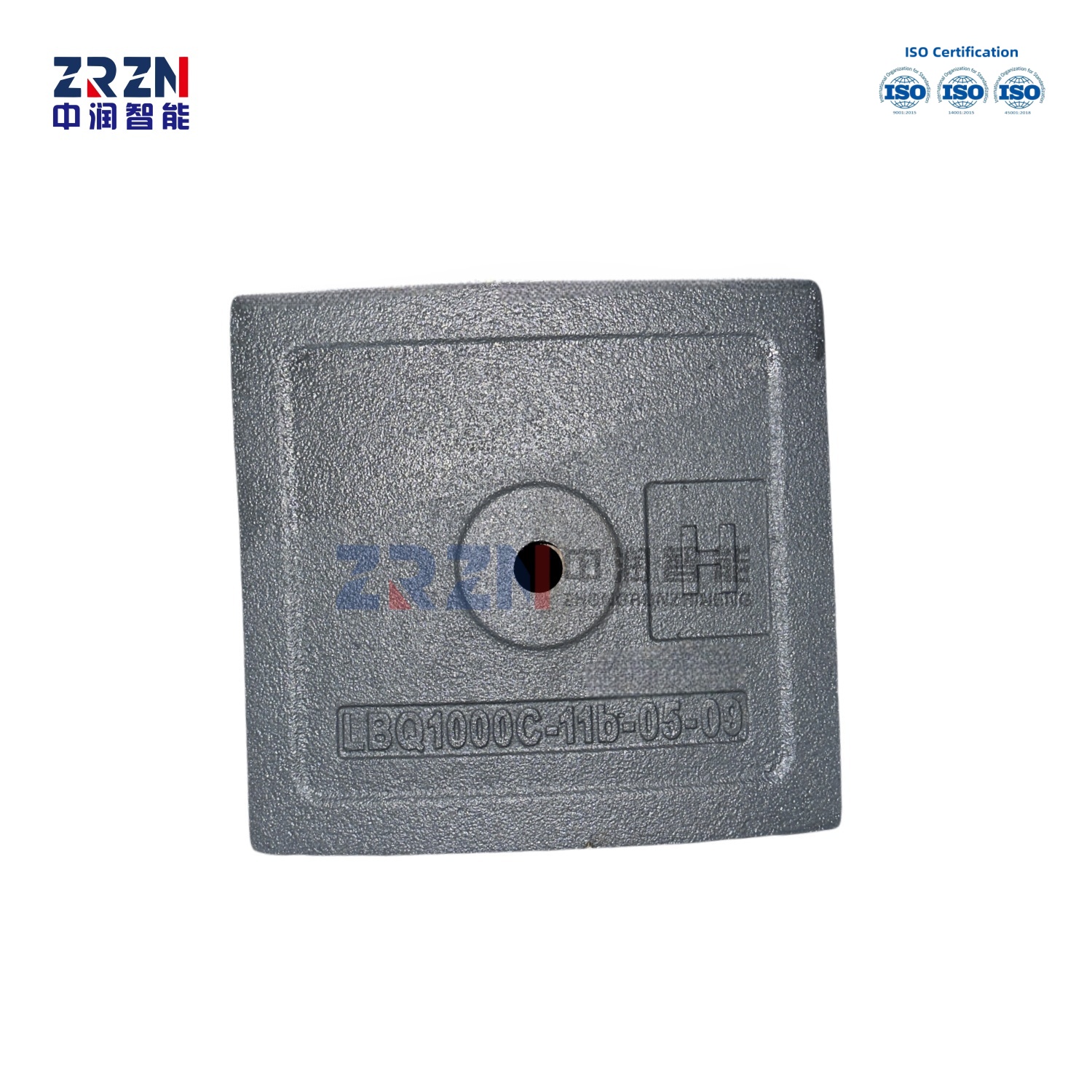

Ensure the consistent mixing quality and operational reliability of your LBQ1500 asphalt plant with our High-Performance Alloy Blade and Arm Set.

Order(MOQ):

1000kgGoods Stock:

1000Payment:

T/T, L/C, Paypal, Western UnionMarket Price:

$3Price:

$1.98/1000kgPrice Range:

5000 - 10000/$1.93Price Range:

1000 - 5000/$1.96Product Origin:

AnhuiColor:

CustomizedShipping Port:

ShanghaiLead Time:

15-30days| Description: |

Ensure the consistent mixing quality and operational reliability of your LBQ1500 asphalt plant with our High-Performance Alloy Blade and Arm Set. As the core agitating components that directly interact with the aggregate mix, these parts endure extreme abrasion, high-impact loading, and constant torsional stress. At Zhongrun Intelligent Equipment, we apply our four decades of metallurgical expertise to engineer not just wear-resistant parts, but dynamic system-critical components designed for peak performance and longevity. Our manufacturing begins with the precision of our lost foam casting line, a technology that excels at producing the complex, aerodynamic geometries required for efficient mixing blades with superior surface finish to minimize drag and material adhesion. The structural integrity of the arms is ensured through our vertical flaskless, high-pressure molding line, which produces castings with exceptional dimensional stability and dense internal structure to withstand bending moments.

Material excellence is foundational. Utilizing computer-controlled medium frequency induction furnaces, we precisely alloy a high-chromium composition optimized for this demanding application. The true differentiator is our proprietary, multi-stage heat treatment process—a "secret recipe" refined over years. This advanced treatment carefully tempers the metallographic structure to achieve an unparalleled balance of core toughness and surface hardness. The result is a component set that combines high flexural strength in the arm to resist deflection, with exceptional impact toughness at the blade's leading edge to absorb shock, all while maintaining a wear-resistant surface. Every Blade and Arm Set is validated in our certified laboratory. We conduct spectral analysis to verify chemical composition, hardness mapping, and mechanical testing to confirm performance against tensile strength and impact toughness specifications.

Produced under our integrated ISO 9001 quality management and digital MES system for full traceability, this set is a direct investment in maximizing your plant's uptime and mix homogeneity. By significantly extending the service life of these critical wear parts, you drastically reduce maintenance frequency, lower long-term spare parts costs, and ensure continuous, efficient production cycles for your LBQ1500 mixer.

Dynamic Performance Engineering: Designed for the dual demands of abrasion resistance and structural load-bearing; blades are optimized for wear, while arms are engineered for high flexural strength and fatigue resistance.

Full Laboratory Validation & Certification: Each set is backed by material test certificates from our in-house lab, confirming alloy composition, hardness profile (HRC), and key mechanical properties like impact toughness.

Designed for Seamless OEM Replacement: Manufactured to exact LBQ1500 specifications for perfect fit and balance, ensuring easy installation and immediate restoration of optimal mixing performance without downtime for modifications.

| Production Line Capabilities |

1、Vertical Flaskless Molding Line: Enables high-speed, large-batch production with minimal dimensional variance.

| Product Parameters: |

| model number | tensile strength σb/Mpa |

tensile strength 0.2/Mpa |

elongation(%) | Fyi | ||

| new model number | equal old model number | minimum value | minimum value | minimum value | HBS Brinell hardness(BHS) |

main metallographic structure |

| QT400-18 | QT40-17 | 400 | 250 | 18 | 130-180 | ferritle |

| QT400-15 | - | 400 | 250 | 15 | 130-180 | ferritle |

| QT450-10 | QT42-10 | 450 | 310 | 10 | 160-210 | ferritle |

| QT500-7 | QT50-5 | 500 | 320 | 7 | 170-230 | ferritle+pearlite |

| QT600-3 | QT60-2 | 600 | 370 | 3 | 190-270 | pearlite+ferritle |

| QT700-2 | QT70-2 | 700 | 420 | 2 | 225-305 | pearlite |

| QT800-2 | QT80-2 | 800 | 480 | 2 | 245-335 | pearliteor tempered structure |

| QT900-2 | - | 900 | 600 | 2 | 280-360 | bainite or tempered martensite |

| Chemical composition(Mass fraction)(%) | |||||||||

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| KmTBN14Cr2-DT | 2.4~3.0 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.10 | ≤0.15 |

| KmTBN14Cr2-GT | 3.0~3.6 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr9Ni5 | 2.5~3.6 | ≤2.0 | ≤2.0 | 7.0-11.0 | ≤1.0 | 4.5~7.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr2 | 2.1~3.6 | ≤12 | ≤2.0 | 1.5~3.0 | ≤1.0 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.15 |

| KmTBCr8 | 2.1~3.2 | 1.5~2.2 | ≤2.0 | 7.0~11,0 | ≤1.5 | ≤1.0 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmlBCr12 | 2.0~3.3 | ≤1.5 | ≤2.0 | 11.0~14.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr15Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 14.0~18.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr20Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 18.0~23.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23.0~30.0 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.1 |

model number |

equal old model number |

Chemical composition(Mass fraction)(%) | Residual element |

||||

| C≤ | Si≤ | Mn≤ | S≤ | P≤ | |||

| ZG200-400 | 2G15 | 0.20 | 0.50 | 0.80 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG230-450 | ZG25 | 0.30 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG270-500 | ZG35 | 0.40 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG310-570 | 2G45 | 0.50 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG340-640 | ZG55 | 0.60 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| Packaging & Shipment |

| FAQ |

1.Q: Could you introduce your company’s business nature and production qualifications?

A: We are a professional manufacturer specializing in wear parts production with over two decades of industry expertise.

2.Q: How can we arrange a visit to your production facility?

A: We warmly welcome visits to our manufacturing base at any time. Our sales team will tailor a dedicated inspection itinerary for you.

3.Q: What core material systems do you utilize?

A: We employ engineered materials such as high-chromium cast iron, ductile cast iron, cast steel, and alloy steel. Material selection is scientifically optimized based on specific operational conditions and performance requirements.

4.Q: What payment methods do you support?

A: We accept international trade settlement methods including T/T and L/C. Flexible payment terms can be negotiated for long-term strategic partners.

5.Q: Do you offer customized branding services?

A: Yes, we provide end-to-end customization solutions covering industrial design, mold development, and product marking.

6.Q: How does your quality assurance system operate?

A: Our facility features professional-grade inspection equipment and a three-stage verification protocol: Incoming material inspection; Batch-specific process quality validation; Pre-shipment certification.

Tags :