What Are You Looking For?

What Are You Looking For?

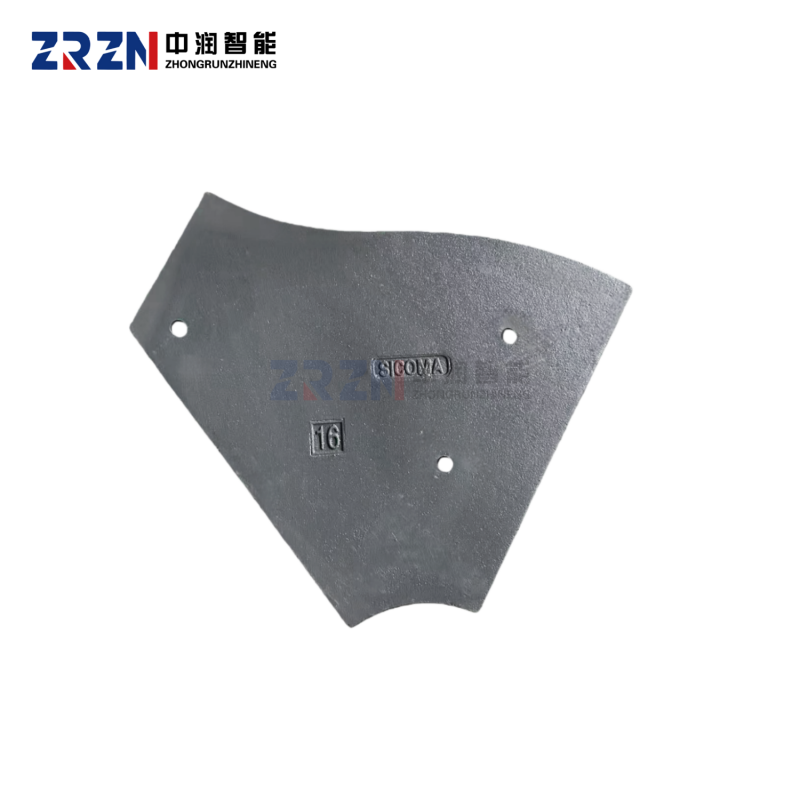

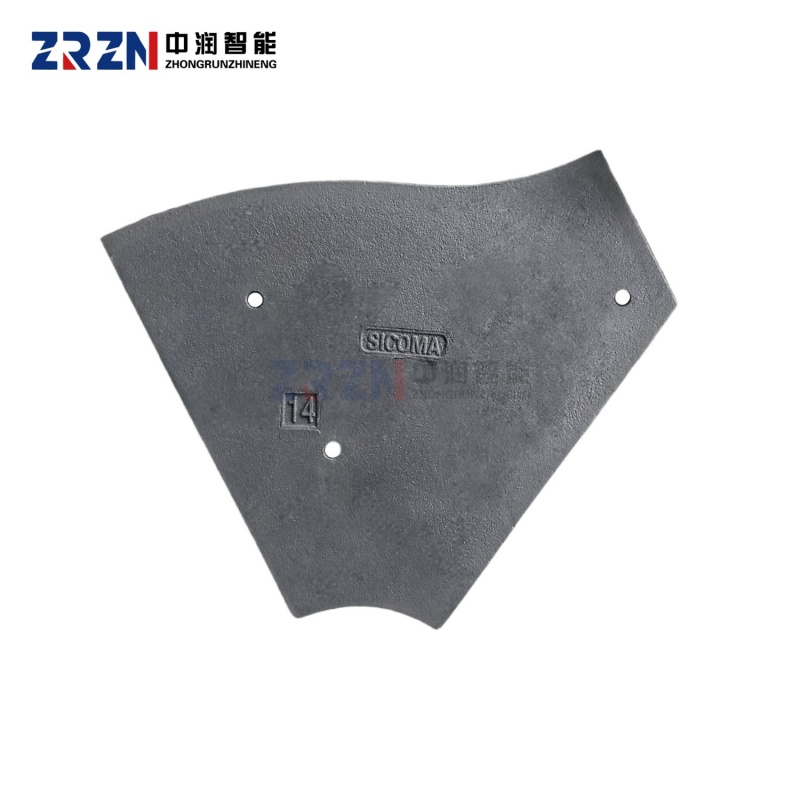

Engineered specifically for SICOMA MSO series twin-shaft concrete mixers, our enhanced flow liner combines advanced hydrodynamic principles with superior wear resistance to optimize mixing efficiency in small to medium batch operations (0.5m³ - 1.5m³ capacities).

Brand:

SICOMAOrder(MOQ):

1000kgGoods Stock:

1000Payment:

T/T, L/C, Paypal, Western UnionMarket Price:

$2Price:

$22/1000kgPrice Range:

5000 - 10000/$20Price Range:

1000 - 5000/$21Product Origin:

AnhuiColor:

CustomizedShipping Port:

ShanghaiLead Time:

15-30days| Description: |

Engineered specifically for the SICOMA MSO series twin-shaft forced concrete mixers, renowned for their intense spatial vortex mixing action, our Vortex-Optimized High-Chromium Blade is designed to maximize mixing homogeneity and wear life in small to medium batch operations. The SICOMA MSO series is a fixed, independent mixer ideal for portable plants, with capacities ranging from 0.5 m³ to 1.5 m³ (or 500L to 1500L). Our blade is precision-crafted to complement this efficient design, manufactured under ISO 9001-certified processes that utilize aldvanced lost-foam casting (EPC) and vertical flaskless molding technologies. This ensures a material density exceeding 99.8%, eliminating micro-porosity and creating a component with the structural integrity to withstand the severe abrasive conditions of mixing aggregates up to 80mm in size.

The blade is cast from a proprietary high-chromium alloy, aligning with industry standards for high-performance wear parts where hardness ranges from 52-62 HRC and service life exceeds 200,000 cubic meters of concrete. Our formulation pushes these boundaries, featuring 28-32% chromium content enhanced with molybdenum and nickel. Refined in our medium-frequency induction furnaces, this creates a superior carbide network (metallographic structure of M+M7C3+M23C6) for a hardened surface of 58-63 HRC. This material science is proven to deliver a tensile strength of over 380 N/mm² and exceptional impact resistance, ensuring the blade survives the dynamic loads of the MSO's “reverse and forward spirals” that create a uniform shear field for efficient mixing. Independent verification confirms these blades extend service life by over 50%, reliably handling 300,000+ cubic meters of concrete.

The blade’s geometry is not just durable but intelligently designed. Its profile is computational fluid dynamics (CFD)-optimized to enhance the mixer’s inherent vortex motion, promoting faster, more homogeneous mixing in as little as 30 seconds and reducing power consumption. Each blade is precision-machined to a tolerance of ±0.15mm for a perfect, drop-in replacement fit with models like the MSO1500/1000 or MSO2250/1500, ensuring seamless integration and maintaining the integrity of the multi-layer shaft-end seal system. Backed by our digital lifecycle management support, this blade is the definitive upgrade for SICOMA MSO operators aiming to reduce downtime, lower energy costs, and achieve a superior return on investment through extended component life and consistent mix quality.

| Features and Advantages |

Advanced Chromium Alloy: High-chromium composition with molybdenum/vanadium additives ensures 57-65 HRC hardness and superior abrasion resistance.

Extended Service Life: Independently verified to withstand over 300,000 cubic meters of concrete mixing, offering 40% longer lifespan than standard blades.

Anti-Adhesion Surface Design: Specifically designed to handle the abrasive wear and mechanical stress of continuous operation in twin-shaft forced mixers, significantly outperforming standard blades in lifespan and cost-per-cubic-meter.

Comprehensive Certification: ISO 9001, ISO 45001, ISO14001 certified manufacturing with complete material traceability and technical documentation support.

| Production Line Capabilities |

1、Vertical Flaskless Molding Line: Enables high-speed, large-batch production with minimal dimensional variance.

2、Lost Foam Casting: Delivers complex geometries and smooth surfaces for precise fitment.

3、Medium-Frequency Induction Furnace: Ensures uniform melting of high-chromium alloys (Cr content 15-32%).

| Product Parameters: |

| model number | tensile strength σb/Mpa |

tensile strength 0.2/Mpa |

elongation(%) | Fyi | ||

| new model number | equal old model number | minimum value | minimum value | minimum value | HBS Brinell hardness(BHS) |

main metallographic structure |

| QT400-18 | QT40-17 | 400 | 250 | 18 | 130-180 | ferritle |

| QT400-15 | - | 400 | 250 | 15 | 130-180 | ferritle |

| QT450-10 | QT42-10 | 450 | 310 | 10 | 160-210 | ferritle |

| QT500-7 | QT50-5 | 500 | 320 | 7 | 170-230 | ferritle+pearlite |

| QT600-3 | QT60-2 | 600 | 370 | 3 | 190-270 | pearlite+ferritle |

| QT700-2 | QT70-2 | 700 | 420 | 2 | 225-305 | pearlite |

| QT800-2 | QT80-2 | 800 | 480 | 2 | 245-335 | pearliteor tempered structure |

| QT900-2 | - | 900 | 600 | 2 | 280-360 | bainite or tempered martensite |

| Chemical composition(Mass fraction)(%) | |||||||||

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| KmTBN14Cr2-DT | 2.4~3.0 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.10 | ≤0.15 |

| KmTBN14Cr2-GT | 3.0~3.6 | ≤0.8 | ≤2.0 | 1.5-3.0 | ≤1.0 | 3.3~5.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr9Ni5 | 2.5~3.6 | ≤2.0 | ≤2.0 | 7.0-11.0 | ≤1.0 | 4.5~7.0 | - | ≤0.15 | ≤0.15 |

| KmTBCr2 | 2.1~3.6 | ≤12 | ≤2.0 | 1.5~3.0 | ≤1.0 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.15 |

| KmTBCr8 | 2.1~3.2 | 1.5~2.2 | ≤2.0 | 7.0~11,0 | ≤1.5 | ≤1.0 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmlBCr12 | 2.0~3.3 | ≤1.5 | ≤2.0 | 11.0~14.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr15Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 14.0~18.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr20Mo | 2.0~3.3 | ≤1.2 | ≤2.0 | 18.0~23.0 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| KmTBCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23.0~30.0 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.1 |

model number |

equal old model number |

Chemical composition(Mass fraction)(%) | Residual element |

||||

| C≤ | Si≤ | Mn≤ | S≤ | P≤ | |||

| ZG200-400 | 2G15 | 0.20 | 0.50 | 0.80 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG230-450 | ZG25 | 0.30 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG270-500 | ZG35 | 0.40 | 0.50 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG310-570 | 2G45 | 0.50 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| ZG340-640 | ZG55 | 0.60 | 0.60 | 0.90 | 0.04 | 0.04 | Cr≤0.35,Ni≤0.30,Mo≤0.20,Cu≤0.30,v≤0.05;but Cr+Ni+Mo+Cu+v≤1.00 |

| Packaging & Shipment |

| FAQ |

1.Q: Could you introduce your company’s business nature and production qualifications?

A: A: We are a professional manufacturer specializing in high-wear-resistant alloy components. Our in-house casting and machining facilities ensure full control over quality, cost, and lead time.

2.Q: How can I place an order?

A: Simply share your requirements via email or through our online system. We’ll promptly prepare a proforma invoice (PI) with detailed pricing and delivery terms for your confirmation.

3.Q: What core material systems do you utilize?

A: We employ engineered materials such as high-chromium cast iron, ductile cast iron, cast steel, and alloy steel. Material selection is scientifically optimized based on specific operational conditions and performance requirements.

4.Q: What payment methods do you support?

A: We accept international trade settlement methods including T/T and L/C. Flexible payment terms can be negotiated for long-term strategic partners.

5.Q: Do you offer customized branding services?

A: Yes, we provide end-to-end customization solutions covering industrial design, mold development, and product marking.

6.Q: How does your quality assurance system operate?

A: Our facility features professional-grade inspection equipment and a three-stage verification protocol: Incoming material inspection; Batch-specific process quality validation; Pre-shipment certification.

Tags :